We are committed to constant technological innovations and improvement of the methods to provide our Clients with the most optimum solution that meets the requirements

METAL PROCESSING:

- Laser engraving;

- Stainless steel blasting;

- Stainless steel polishing;

WOOD PROCESSING:

- Format saw;

- Band saw for precise splitting;

- Longitudinal wood cutting;

- Milling – high performance;

- Fine planing and thickening;

- Edging;

- Drilling: vertical and horizontal;

- Grinding, sanding;

- Spray-painting & lacquering (camera);

- Assembly;

3D LASER CUTTING

Prima Power – Rapido 3D

Flexibility working with different profiles and structures with limits:

X: 4080mm, Y: 1530mm, Z: 765mm working with one chamber;

X: 2x1600mm, Y: 1530mm, Z: 765mm – working with two chambers;

POWER – 3KW

CUTTING THICKNESS:

- Carbon steel – up to 8mm;

- Stainless steel – up to 8mm;

- Aliuminium – up to 5 mm;

- Copper – up to 5mm;

- Brass – 6mm ;

WELDING THICKNESS – up to 4 mm

CNC SPINNING

KH-600-R-H-FF

- Max diameter of item – 550 mm;

- Max item hight – 700 mm;

- Max material thickness – 2.5 mm;

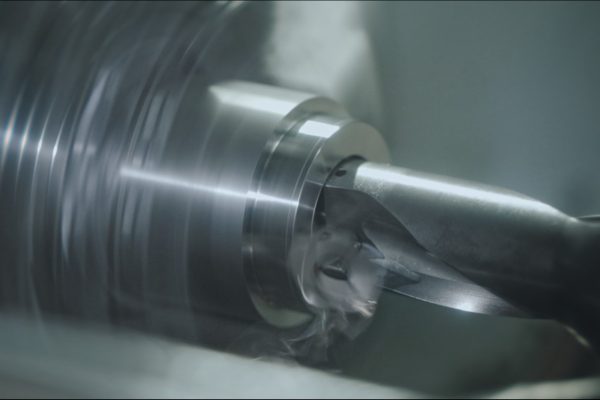

CNC TURNING

Goodway GS260YS

- Max item diameter – 400mm;

- Max item length – 600mm;

- RPM: 4000/min;

- Bar feeder – up to 65 mm diameter

WELDING

- Manual welding:

TIG – 4 working centers ;

MIG – 4 working centers; - Orbital welding (automatic):

ORBIWELD OW 76S – 2 working centers;

ORBIMATIC – 3 working centers; - Robotic welding:

PRIMA POWER – RAPIDO 3D – 2 working centers

STAINLESS STEEL SURFACE TREATMENT

- Laser engraving – 1 pc.

- Sandblasting automatic chambers – 2 pc.

- Polishing equipment – 4 working centers;

- Electropolish – 1 working center;

ASSEMBLY

We perform manual assembly and packing services.

Each project is special, depending on customer needs, evaluating quantities, product size and complexity, we work out most efficient approach and layout.